Advanced Coating Technology

ThinTech Hub

Articles

Unlocking the Secrets of Coating Technology

November 17, 2023

In a significant stride towards showcasing cutting-edge innovations in surface protection, ThinTech Coating proudly participated in the esteemed Carcon Fair …

September 26, 2023

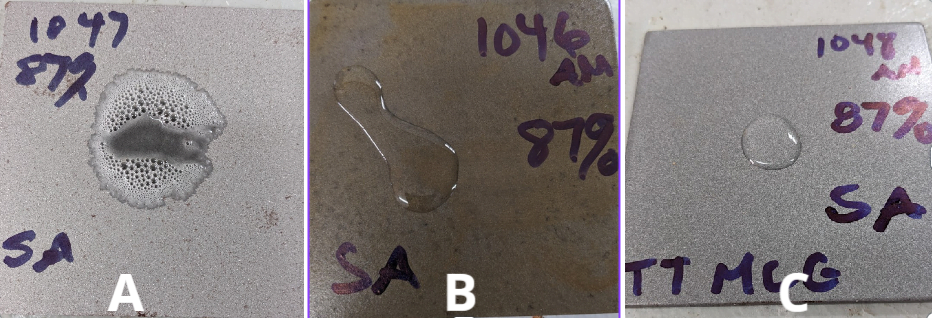

Introduction In this Lab study, we examine the reaction and performance of 87% sulphuric acid on coated and uncoated carbon …

July 12, 2023

Water, with its seemingly gentle nature, can wreak havoc on masonry surfaces if left unchecked. From crumbling bricks to unsightly …

June 9, 2023

Have you noticed the once vibrant pigments of your old paint job fading away, leaving your surfaces dull and lackluster? …

May 26, 2023

Wind turbines are crucial for generating clean and renewable energy, but they face challenges such as oil leakage and subsequent …

May 15, 2023

As environmental concerns continue to gain prominence worldwide, regulatory bodies are implementing stricter guidelines to protect the environment from contamination …

Application Tips

Coating Solutions: Dos and Don'ts for Pro Results.

To access our exclusive tips and insights from industry experts, we invite you to create an account today. By registering with us, you’ll gain access to a wide range of information and resources related to coatings, including application techniques, best practices, and troubleshooting tips. Whether you’re a seasoned professional or just starting out in the coatings industry, our expert guidance will help you achieve better results and advance your career.

You must be login in order to see this content

FAQ

Frequently Ask Questions.

ThinTech has made it our mission to provide long-term cost-effective solutions from exterior structural to industrial asset production our coatings stand in harsh environments

ThinTech coatings are clear hybrid nano coatings paired in a solvent-based delivery system. Our coatings bond at the molecular level with the substrate using nanotechnology; tiny nanoparticles and resins are embedded deep into the substrate's pores to form a non-permeable chemical bond far exceeding traditional paints and coatings protection. This ensures durable long-term solutions for corrosion prevention and asset protection

ThinTech metal coat is an ideal solution for corrosion prevention from hydrocarbon exposure, UV exposure, high humidity, wet climate regions, and coastal areas. It can be used as a straightforward metal solution and flash rust prevention ThinTech has excellent adhesion properties and is an ideal top coat for painted surfaces ThinTech provides a durable shell that is non-permeable and will protect for years to come.

Concrete coatings are applied to concrete surfaces for a variety of reasons, including protection, durability, and aesthetics. They are designed to improve the performance and appearance of concrete by providing a barrier against wear, tear, and damage caused by environmental factors, such as moisture, UV radiation, chemicals, and abrasion. Concrete coatings can also enhance the look of concrete by providing color and texture options that can be customized to match the surrounding environment. Additionally, some coatings can improve safety by adding slip-resistance to the surface of the concrete, making it less slippery and reducing the risk of accidents. Overall, concrete coatings can provide a cost-effective solution for improving the lifespan, performance, and appearance of concrete surfaces.

Under insulation, corrosion is an all too common unseen problem. This problem can easily be prevented for less than 18 cents per square meter of estimated painted surface carbon steel. Before insulation installation, apply 2.5 mils wet film thickness to the painted surface of the pipe. Allow three to five hours of dry time before insulation encapsulation. This will ensure zero rust on all properly applied areas for years.