Advanced Coating Technology

Concrete Coating

Available in:

Unlock the Best Deals: Request a Quote Today and Save Big!

Get a quote today for our reliable and affordable coating products. We offer custom pricing based on your specific needs and pride ourselves on high-quality work and exceptional customer service. Contact us now for a personalized quote and all the answers you need to achieve your project.

Need a durable and top-quality metal coating solution for your project? Look no further! Our team offers customized quotes to meet your exact requirements and budget. Our products feature top-of-the-line materials for optimal performance and durability. Fill out our request quote form today to get started!

Fill out our concrete coating request form to protect and enhance your concrete surfaces. Our coatings are durable and come in a variety of colors and finishes, making them ideal for a range of applications. Simply provide your contact information and project details below, and we will send you a personalized quote and coating recommendations promptly. Get started today!

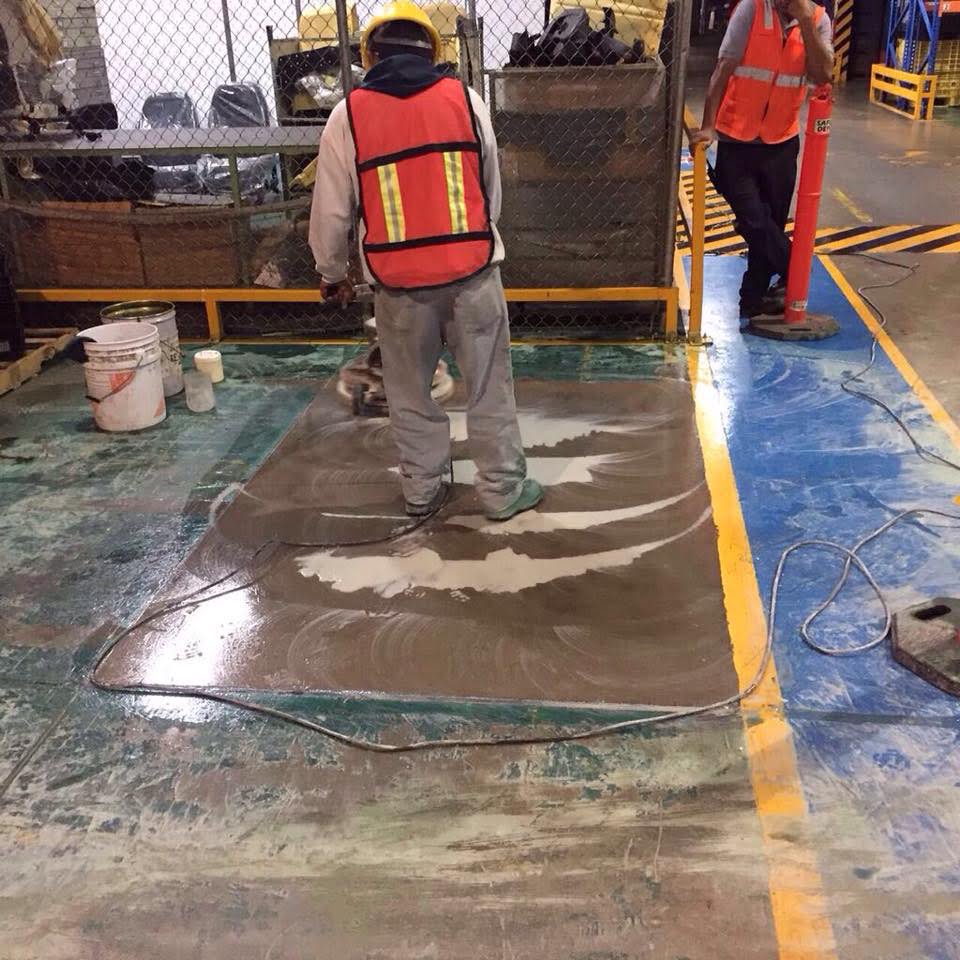

Concrete Coating

- Provides superior moisture protection, which is essential in preventing the growth of mold and mildew, as well as protecting against water damage.

- Effective against most types of stains, including those caused by oil, grease, and other common exterior contaminant. This means that concrete surfaces will stay looking clean and fresh, even with heavy use.

- Stain resistance, Thin Tech Concrete Coating is also designed to be effective against mild acids. This makes it ideal for use in industrial or commercial settings where exposure to corrosive substances is likely.

- Effective against bird and animal waste, making it ideal for use in coastal spaces or other areas where waste from these sources are a concern.

Thin Tech Concrete Coating is a versatile and effective solution for a wide range of concrete-related problems. Whether you are looking to protect your concrete surfaces from moisture, corrosion, stains, mild acids, bird and animal waste, or hydrocarbon, this coating has you covered. With its superior protection and ease of use, Thin Tech Concrete Coating is the ideal choice for anyone looking to keep their concrete surfaces looking good and functioning well for many years to come

Instruction of Use

Surface

Surface must be clean, dry, and in good condition. Remove all oil, dust, grease, dirt, and foreign material. Avoid silicon, as Thin Tech will not adhere to it. If surface was previously sealed, sprinkle water to test. If water beads up, remove the coating/sealer before application. Let dry to less than 13% moisture content. New surfaces should be abraded and tested for ph balance. Previously painted surfaces should be cleaned and abraded.

Solution

Thintech Concrete Coating offers a comprehensive solution to various concrete-related problems, including moisture, stains, mild acids, bird and animal waste, and hydrocarbons. The coating is designed to provide a durable and long-lasting barrier to these damaging factors, ensuring that concrete surfaces stay looking good and functioning well for many years to come.

Characteristics

| Appearance: | Clear |

| Finish: | Gloss or Satin |

| Vehicle Type: | Solvent Base |

| Flash Point: | (C Penskey-Martens closed Cup) -9c/15F |

| VOC: | Less than 100 g/L |

| Weight per Gallon: | 7.36 lb/gallon |

| Non-Breathable |

Spread Rate

Recommended Spread Rate per coat:

- Wet mils: 2.5-3.5 on horizontal surfaces. Vertical surfaces may need wet on tack to avoid runs

- Dry mils: 1.5 – 2.1

Coverage

Coverage: 400-600 sq ft./gal (approximate)

Coverage will vary depending on the porosity and texture of the substrate as well as the applicators method of application.

Surface Preparation

The surface that is to be coated with ThinTech must meet certain requirements to ensure a successful application. Firstly, it must be completely cleaned and dried to remove any trace of oil, dust, grease, dirt, or any other foreign material that may hinder the bonding process. If the surface has previously been exposed to oil, it is important to ensure that all remnants of the oil have been removed and that the surface is no longer prone to wicking action.

This is because the presence of oil or any other foreign material can prevent the ThinTech coating from forming a proper bond with the surface. As a result, the coating may start to delaminate and peel off, reducing its effectiveness and lifespan.

It is also crucial to ensure that the surface is in sound condition, free from larges cracks, crumbling, or any other imperfections that may weaken the bond between the coating and the surface. If the surface is damaged or in poor condition, it may be necessary to repair it before applying the ThinTech coating.

By following these simple steps, you can ensure that the ThinTech coating is applied correctly and will provide long-lasting protection for your surface. Whether it’s a floor, wall, or any other type of surface, ThinTech is designed to be durable and resistant to a wide range of environmental conditions, making it the ideal choice for any surface protection needs.

It is important to remove all contaminants such as dirt, dust, grease, oil, loose particles, laitance, coatings, and curing agents. To prepare the surface for ThinTech application, smooth surfaces should be treated to achieve a 600 grit finish by sand blasting or grinding with a floor machine. Before application, it is also important to test the surface for the proper pH balance, which should be between 7 and 9. Thorough cleaning is necessary to ensure the surface is free from any residue, and it should be allowed to dry completely. The moisture content of the surface should not exceed 13% in order to guarantee the best results from ThinTech application.

It’s essential to remove any foreign material and roughen the surface using 600 grit sandpaper before applying ThinTech Concrete Coating. If the paint is chipping or severely damaged by weather, a fresh coat of paint may be necessary. If a repaint is required, follow the instructions provided by the paint manufacturer and wait the specified time before applying ThinTech Concrete Coating.

Application Instructions

To ensure proper adhesion and the desired appearance, it is recommended to test ThinTech Concrete Coating in a discreet location due to the diverse nature of concrete and masonry surfaces, as well as various application techniques and environments. The application of this technology may result in a slight improvement or alteration of the natural surface, and a shine in either a gloss or satin finish, depending on your preferred option. The variety of textures and porosities of concrete and masonry surfaces can greatly impact the final result, making it important to test before full-scale application.

ThinTech Concrete Coating can be applied using a pump sprayer with a grey or red fan tip or through rolling with a high-density, ultra smooth roller an airless sprayer may use for larger projects. To avoid any drips or accidental coating on surrounding surfaces, it’s important to cover them before starting the application process. Adequate ventilation should be maintained, and all possible ignition sources should be removed from the area. It’s also crucial to ensure that the temperature during outdoor application is within the range of 45° F and 105° F, and that there’s no chance of rain for at least 5 hours after completing the coating process. Proper precautions should be taken for natural elements.

Begin by thoroughly shaking the contents of the container to re-suspend any ThinTech particles that may have settled to the bottom. This is typically about 1⁄4” of buildup. Re-shaking every 15-20 minutes is necessary to maintain the re-suspension of the particles. It is recommended to use a high-quality acetone/alcohol proof pump sprayer equipped with a grey or red fan tip, as opposed to a standard tip, to achieve the best results.

Hold the tip at a distance of 8” to 10” from the surface being coated and apply the product in a cross pattern, either left to right, up and down, or in a circular motion. Avoid applying the coating too thick and ensure it does not puddle, as this can lead to surface tension and potential bubbles or delimitation. If a second coat is necessary, wait 24 hours for the surface to dry, then abrade it with 220 grit sandpaper using a buffing floor machine to allow the second coat to bond. Finally, clean the surface of any dust before reapplying.

By following these steps, you can ensure a flawless application of ThinTech and enjoy the benefits of its advanced coating technology for years to come.

Shake the contents of the container thoroughly to re-suspend the ThinTech particles that have settled at the bottom. There will typically be around 1⁄4” of buildup in the bottom, which needs to be re-suspended every 15-20 minutes to ensure proper performance. Roll the ThinTech onto the surface using a high-density ultra smooth roller in a cross-pattern, moving from left to right and then up and down, making sure that the roller is always completely saturated. Avoid applying a second coat unless there is a flaw in the first application. If a second coat is required, wait for the surface to dry for 24 hours, then abrade it with 220 grit sandpaper using a buffing floor machine to allow for proper bonding. Sanding is necessary for the second coat to adhere to the first one. After sanding, clean the floor of dust and reapply.

Dry Time

Drying Time (@ 77 F, 50% RH):

Drying time is Temperature, humidity and film thickness dependent. (The higher the humidity the faster the dry time).

- Touch: 1 hour

- Through: 2-4 hours

- Walk on: 8 to 12 hours

- Full Cure: 7 Days

Interruption of Work

ThinTech recommends that applicators should stop the application process at expansion joints or any other notable points in order to pick up where they left off at a later time. In the event of any damage to the area, it is important to sand down the affected area using 600 grit sandpaper on a floor machine and reapply the product. To ensure a successful repair, it is important to keep the area free of traffic for at least 8 hours and keep moisture away from the repaired area. The curing process should take 7 full days, during which time it is important to avoid disturbing the area in any way. By following these guidelines, you can ensure that your ThinTech application will be of the highest quality and will provide long-lasting durability and protection.

Clean Up

ThinTech strongly recommends cleaning tools and equipment with acetone thoroughly before the product dries. This is because once the product dries, solvents will not be able to clean it off. ThinTech products are designed to be tough and durable, but proper preparation is essential for ensuring the best results. By cleaning tools and equipment with acetone, you can avoid any residue that may interfere with the application of ThinTech products. This step is especially important when you are using different tools or equipment for each application.

Moreover, ThinTech products are made with the latest advancements in nanotechnology. This means that they are engineered to provide excellent performance and long-lasting results. By using ThinTech products, you can enjoy the benefits of advanced technology and high-quality products. Whether you are working on a new project or just need to make a few touch-ups, ThinTech has you covered. So, before you start your next project, make sure to follow the recommended steps to ensure that your tools and equipment are ready for use.

Caution

ThinTech always emphasizes the importance of wearing personal protective equipment (PPE) when working with its products. All workers must wear OSHA approved 1910.134 and ANSI Z88 2 respiratory protection to ensure their safety from inhaling any harmful substances. It is also imperative that enclosed work areas are equipped with proper ventilation systems to minimize the risk of inhaling harmful fumes. In the unlikely event of inhalation, it is important to move to fresh air and seek immediate medical attention if physical difficulties occur.

In addition to respiratory protection, it is also important to wear butyl-rubber gloves and other skin protection to avoid direct contact with the skin. In the event of skin contact, the affected area must be thoroughly washed with soap and water. Chemical safety goggles or splash shields are also required to protect the eyes, and contacts must not be worn without proper eye protection. If eye contact occurs, immediately flush the eyes with water for 15 minutes and seek medical attention. Finally, if any ThinTech product is accidentally swallowed, it is essential to rinse the mouth thoroughly and seek immediate medical attention.

Care & Maintenance

To achieve a shiny finish, a ThinTech Coatings Buffing Pad can be used for buffing the floor. With this advanced technology, wax coating is no longer necessary. In case of any damage, re-abrade the area with 600 grit sandpaper using a floor machine and reapply the coating. To ensure proper curing, prevent any foot traffic on the repaired area for at least 8 hours and keep moisture away from it. Allow the area to cure for 7 days full cure before use.

Contact Info

- +84 38 8743584

- info@thintechcoatings.com

Safety Data Sheet

Technical Data Sheet

Applications

Superior Surface Protection

Superior Metal Surface Protection.

Corrosion is a primary concern in the oil and gas industry, as it can cause significant damage to equipment and infrastructure, leading to costly repairs, downtime, and potential safety hazards. Therefore, it is essential to take proactive measures to prevent corrosion from occurring.

Superior Concrete Surface Protection.

Exterior building surfaces are exposed to various environmental factors, including moisture, air pollution, and temperature changes, all of which can lead to corrosion and other forms of damage. ThinTech Coating offers a range of specialty nano-coatings designed to protect exterior building surfaces and prevent decay.

Superior Metal Surface Protection.

Industrial heavy equipment is often exposed to harsh environments and corrosive substances, which can lead to corrosion, rust, and other forms of damage. ThinTech Coating offers specialty nanocoatings that are designed to protect heavy industrial equipment and prevent corrosion.

Superior Concrete Surface Protection.

Protecting a parking structure’s surface is crucial to ensure its longevity and safety for vehicles and pedestrians. ThinTech nanotechnology coatings offer an ideal solution for preventing corrosion and other forms of damage to parking structures, such as oil stains, chloride, ion exposure, and harsh environmental exposure.

Superior Metal Surface Protection.

Maritime environments can be incredibly harsh, exposing ships and other watercraft to a range of corrosive elements such as saltwater, humidity, and temperature changes. Protecting these surfaces is essential to prevent corrosion and further damage that can compromise the vessel’s or structure’s safety and integrity. ThinTech nanotechnology coatings offer an effective solution for protecting marine surfaces.

Superior Concrete Surface Protection.

Balconies and walkways are exposed to many elements and heavy foot traffic unfortunately these areas suffer from heavy staining and grime buildup. ThinTech concrete coating will provide a deep penetrating natural color enhancing clear nano coating that is impermeable to chemicals and common staining such as oil coffee juices hydraulic fluids diesel fuel and salt exposure. ThinTech concrete coating helps protect and prevent structural exterior and internal corrosion

Superior Concrete Surface Protection.

When it comes to spill containment, you need a product that combines innovation, reliability, and superior performance. That’s where ThinTech Coatings Concrete steps in. Our cutting-edge technology and advanced formulations provide the ultimate protection for your concrete surfaces against spills, leaks, and potential environmental hazards.