Wind turbines are crucial for generating clean and renewable energy, but they face challenges such as oil leakage and subsequent runoff. In this article, we will explore the role of a high-quality coating solution in mitigating these issues. Discover how the right coating can repel oil, resist adhesion, prevent corrosion, simplify maintenance, and ultimately ensure the optimal performance and longevity of wind turbines. Join us as we uncover the secrets behind safeguarding wind turbines with an effective coating solution.

Oil Runoff vs. Coating Superpowers: Unleashing the Wind Turbine Shield!

A good coating solution is recommended against oil running down on wind turbines for several reasons:

- Protection against corrosion: Wind turbines are often exposed to harsh environmental conditions, including high winds, rain, and saltwater in coastal areas. These conditions can cause corrosion of the turbine components, including the tower, blades, and internal machinery. A high-quality coating acts as a barrier, protecting the underlying surfaces from direct contact with oil, moisture, and corrosive elements.

- Enhanced aerodynamic performance: Oil running down the surface of wind turbine blades can create a layer of residue that increases drag and disrupts the smooth flow of air. This can reduce the efficiency of the turbine and decrease its overall power generation. A proper coating solution can help maintain the aerodynamic profile of the blades, ensuring optimal performance and energy production.

- Ease of maintenance and cleaning: Applying a suitable coating to wind turbine surfaces can make it easier to clean and maintain them. A well-designed coating can repel oil, dirt, and debris, preventing them from adhering to the surface. This simplifies the cleaning process and reduces the frequency of maintenance activities, ultimately saving time and resources.

- Prolonged lifespan and reduced downtime: By providing protection against oil contamination and corrosion, a good coating solution can help extend the lifespan of wind turbines. Corrosion can weaken the structural integrity of the turbine components and lead to premature failure or breakdowns. By preventing oil from running down and causing damage, a coating solution can minimize downtime and maintenance costs associated with repairs or replacements.

- Environmental considerations: Oil leakage from wind turbines can have negative environmental impacts, particularly if it reaches the ground or nearby water sources. A reliable coating solution can help contain and prevent oil leaks, reducing the risk of pollution and minimizing the ecological footprint of wind energy installations.

In summary, a good coating solution for wind turbines provides protection against corrosion, maintains optimal aerodynamic performance, facilitates easier maintenance and cleaning, extends the lifespan of the turbine, and reduces environmental risks associated with oil leakage.

How a Coating Solution Saves Wind Turbines from Oil Runoff!

A good coating solution can help prevent oil from running down on wind turbines through the following mechanisms:

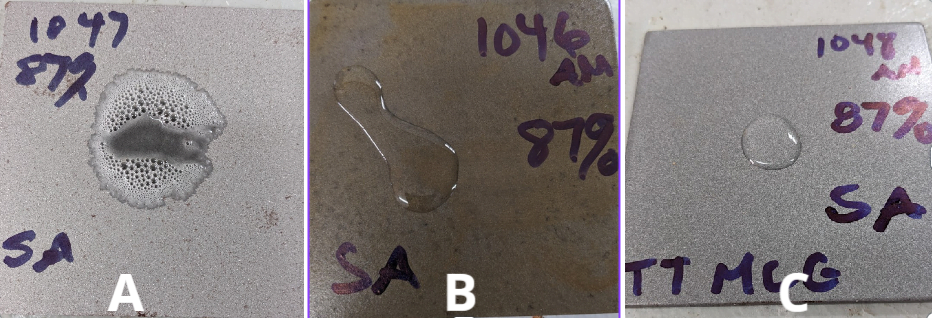

- Surface repellency: A high-quality coating is designed to have a hydrophobic or oleophobic (oil-repelling) property. When applied to wind turbine surfaces, this type of coating forms a thin, protective layer that repels liquids, including oil. Instead of spreading and running down the surface, the oil tends to bead up and roll off, reducing the chances of it reaching critical components or causing damage.

- Adhesion resistance: A good coating solution for wind turbines has excellent adhesion resistance, meaning that it minimizes the ability of oil to adhere to the surface. The coating forms a smooth and non-porous barrier that prevents oil from sticking and spreading across the turbine components. This reduces the likelihood of oil accumulation and subsequent running down of the surface.

- Anti-corrosion properties: The coating solution may also possess anti-corrosion properties. Even if oil comes into contact with the coated surface, the coating can provide a protective barrier that inhibits the corrosive effects of the oil. By preventing corrosion, the coating helps maintain the integrity of the wind turbine components and reduces the risk of oil leakage or failure.

- Easy cleaning: A good coating solution can make cleaning and maintenance of wind turbines easier. The surface properties of the coating prevent oil from adhering strongly to the surface, allowing for more efficient removal during cleaning operations. This reduces the time and effort required for cleaning and minimizes the potential for oil to accumulate and run down the turbine.

- Long-lasting performance: A high-quality coating solution is designed to have long-lasting performance under the harsh environmental conditions experienced by wind turbines. It should be resistant to weathering, UV radiation, and abrasion, ensuring that it maintains its oil-repelling and protective properties over an extended period. This durability helps to prevent oil from running down and protects the turbine surfaces effectively.

By employing these mechanisms, a good coating solution can significantly reduce the likelihood of oil running down on wind turbines, thereby minimizing the associated risks and maintaining the optimal performance and longevity of the turbine.